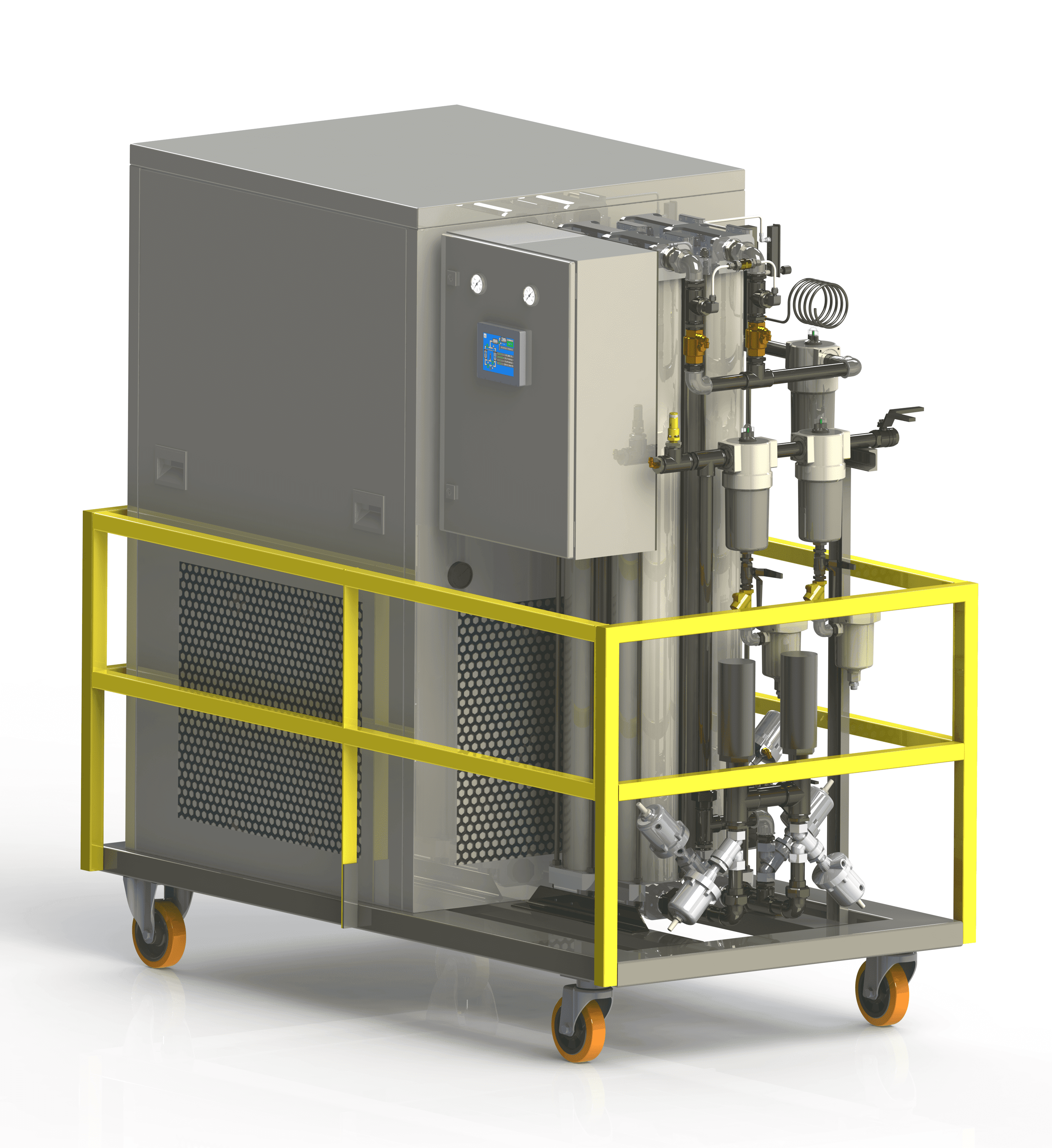

Technology

Coolers have been designed to improve the productivity of the plastic bottle industry. They use your network’s compressed air to produce air that is: cold, dry, dust-free and sterile if required. The air is used to blow mould plastic bottles.

Accelerating the cooling process has several effects:

- Reducing the plastic bottle’s downtime

- Increasing machine output

- No injection of liquefied gas

- Gradual cooling without any cold spots

- Reducing internal stresses in the material

- Increasing the cooling heat flow

Technical specifications:

- Air filtration

- Drying at a dew point of -50°C

- Cools down air up to -40°C

- Water cooling as standard

- Voltage for adsorption dryers: 230V-1-50

- Maximum pressure: 10 bar

- Optional: 16 bar (pressure)

- Advertised flow rates at stated temperature conditions