CO2 Adsorber Technology

How it works:

- Adsorption principle

- CMS activated carbon columns

- How cycles work:

Adsorption > Regeneration > N2 flushing - Models: single or double vessel

In order to reduce oxygen ingress and reach oxygen levels below 1% inside the chambers, adsorbers should incorporate a nitrogen flushing cycle for carbon or should operate with a pressure management system.

Single Vessel CO2 Adsorber

The single vessel adsorber is designed for 1-3 chamber adsorption.

Technical specifications:

- Automatic management

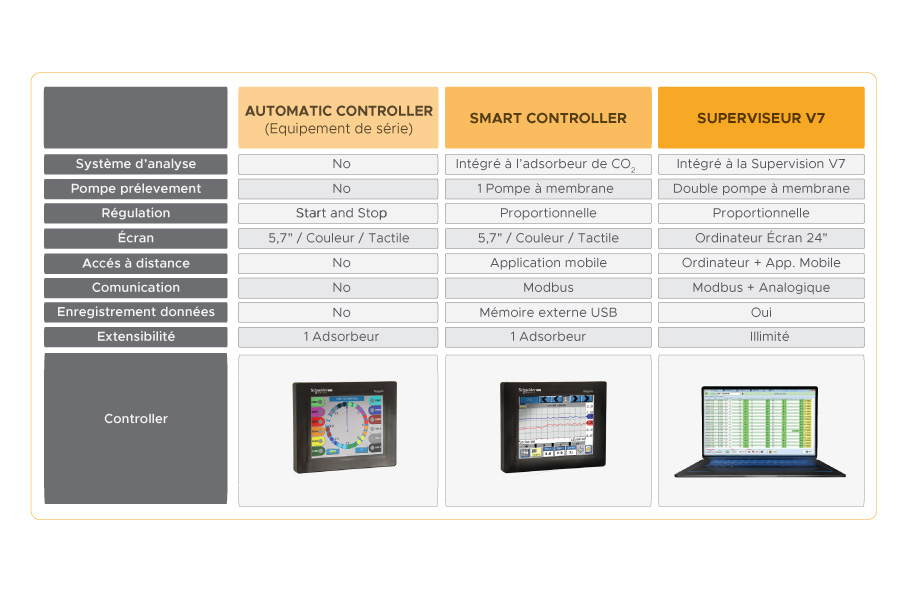

- Programme: V7 technology or Smart Controller

- Display: touch screen, colour

- Remote control

- Automatic alarm system

- Purity rate: 0.7% to 1% (O2/CO2)

- ULO/XLO compatibility

- Dimensions and weight: depending on the model

Double Vessel CO2 Adsorber

The double vessel adsorber is designed to function continuously on the assigned chambers.

Technical specifications:

- Automatic management

- Programme: V7 technology or Smart Controller

- Display: touch screen, colour

- Remote control

- Automatic alarm system

- Purity rate: 0.7% to 1% (O2/CO2)

- ULO/XLO compatibility

- Dimensions and weight: depending on the model

Automatic Control

- ABSOGER CO2 adsorbers are designed to operate on multiple chambers and are controlled by an automatic control system.

- The control system triggers each connected device to start operating. An algorithm is used to run the machines for the exact time necessary to reach the set rates.

- Standard equipment includes a basic PLC with a colour touch screen controlling the adsorber: it controls and carries out different regeneration and adsorption cycles depending on the CO2 content required.