GA: Customised nitrogen generator on a platform

Discover our industrial solutions for on-site nitrogen generation. We manufacture customised equipment to suit your needs.

Our solutions are used to upgrade the production processes of a large number of French manufacturers.

Since 1988 ABSOGER, under its CARBOTRADE brand, has manufactured over 1,300 nitrogen generators used for various applications in many industrial sectors. CARBOTRADE has become one of the major players in the sector thanks to its ability to adapt its nitrogen generators to the industry’s specificities.

Carbotrade manufactures customised machines which are “made in France", entirely manufactured in our factory in the South West of France.

By choosing CARBOTRADE, you are choosing a partner who will listen to your needs, who will support you throughout your project, providing a customised result and certified quality

The industrial field is vast and each field has its own particularities: At CARBOTRADE we are aware of this, and we take it into account in our manufacturing processes. Each machine has its own specific features and meets a specific need, which can be adapted to a wide range of applications.

Whether you are in the food, pharmaceutical, automotive, metallurgical industry or any other industry, CARBOTRADE will be your project’s advisor from conception to completion. Understanding your needs, coming up with a suitable solution, implementing it and following up on it: those are the guarantees that make CARBOTRADE one of the leaders in nitrogen generation.

Packaging under a modified atmosphere is used to package products for which shelf life is essential.

The principle consists in replacing the air in the tray with nitrogen. This process slows down bacterial growth inside the tray, preserves the product from the effects of ageing and therefore increases its shelf life.

This type of packaging is suitable for all types of products such as fish, ready meals, cold cuts and sausages.

Following the same process, we offer solutions for nitrogen packaging machines. Nitrogen supply is a key element in the production chain of nitrogen packaging machines, both for machine efficiency and for costs of use.

With CARBOTRADE, you can produce your own nitrogen and lower your supply costs. You will be achieving economies of scale and will take control of your production costs.

Nitrogen also plays an essential role in the bottling process of beer and wine, by measuring the dissolved oxygen and carbon dioxide. Controlling these gases is essential for producing quality wine and beer.

With CARBOTRADE, you can become your own nitrogen supplier and secure your supply from the press to the bottling plant. You can control your costs and your production.

Carbonated and non-carbonated beverages are no exception to the rule: pressurisation is a key element in production, to maintain quality and to avoid damage during transport.

Our bottle pressurisation techniques are based on nitrogen generation and use. The properties of nitrogen make it perfectly suitable for beverages: evaporation, expansion and above all protection against oxidation. Our solutions will help you increase quality, efficiency and cost-efficiency.

Many pharmaceutical laboratory facilities require atmosphere control techniques and potentially the production of certain gases.

Nitrogen supply, hypoxia, anoxia or other atmospheric conditions are often required to study and manufacture drugs.

CARBOTRADE will be your advisor to assist you in setting up your laboratory equipment to control atmospheric and gas conditions.

Our machines have a number of pharmaceutical applications. Medicine packaging is one of the main ones. At this stage, gas control is essential to ensure that medicines meet the production standards applicable in the country.

There are strict conditions regarding air composition and purity during the packaging process. Nitrogen input and purity at the inlet and outlet of the process are different, and our solutions can be used to control this crucial step, achieving high and precise purity levels.

The same applies when going through the pressurised oven. Pressure conditions must be highly precise and strictly controlled to ensure quality. Nitrogen generation is one of the key components to achieving this.

CARBOTRADE and its customised nitrogen generation solutions will help you take control of your production line by becoming your own nitrogen supplier, so that you can control your costs and needs.

CARBOTRADE is also active in the automotive industry, where gas control is applied in many areas and fields.

Electronic soldering ovens are an example. Atmosphere control, nitrogen generation and injection are essential elements in the welding process.

Our customised CARBOTRADE solutions are manufactured according to your needs and guarantee welding quality, fewer defects and lower gas-related risks.

Tyres are also a key field in the car industry that strongly relies on using gases correctly.

When tyres are manufactured, the use of nitrogen is subject to certain standards for injected pressure and purity. Hence, dealing with nitrogen generation and injection constitutes a challenge for the company.

Our equipment will help you manage gases and monitor rates, to control nitrogen supply and the quality of the tyres manufactured.

Managing gases is also crucial for inflation. It protects the tyres from wear and tear and ensures durability.

When air is injected into the tyres, oxygen passes through the membrane increases wear and tear through oxidation. Injecting pure nitrogen counteracts this undesirable effect by preserving the membrane from oxidation.

CARBOTRADE assists you with the supply and control of gases for your tyres, from manufacture to inflation.

Finally, gas management is also used in the car painting stage and brings a number of benefits.

First of all, pressure management is used to improve painting equipment efficiency. It also limits the number of impurities by reaching a very high level of nitrogen purity. Efficiency and quality are therefore improved.

CARBOTRADE provides you with solutions suitable for all these automotive applications and supports you in your efforts to control gases.

In metallurgy, gases play a key role in shaping the material, so controlling them is crucial for production.

It is notably the case for production line cooling. At this stage, gases are used for their properties, which can control production line cooling. To achieve this, of course, it is essential to control gases and the administered rates to ensure that cooling is optimal and does not affect production.

In addition to controlling production, our technologies are designed to ensure the protection of materials. An example is the welding of stainless steel pipes, where gases are used to protect the tubes.

During welding, the material is subjected to harsh conditions of heat and pressure. This can cause a number of visible alterations, such as deformation or other visible traces.

The same applies to copper brazing. Brazing is somewhat similar to welding, in that it can potentially affect the quality of materials. That is why controlling the gases present in the equipment is beneficial for product quality and for the sustainability of the company’s activity.

Managing gases can be done to counteract the undesired effects and protect your materials while ensuring production runs smoothly.

Metallurgy uses a number of various furnaces, for which CARBOTRADE solutions can be used:

For heat treatment furnaces with nitrogen injection, our customised generators control the injection parameters.

Nitrogen is also an essential factor for silver dehydrogenation furnaces and tungsten carbide furnaces, which need to be loaded under nitrogen.

Laser cutting is used in a large number of industries. The costs, risks and constraints of this technique are paramount for the sustainability of industrial companies.

Nitrogen in laser cutting is used for two things: cutting with a very high pressure stream, and reducing deformation. Highly pure nitrogen limits the effects of damage to material quality.

CARBOTRADE offers solutions to improve the quality of laser cuts and to meet your nitrogen needs.

The plastics industry is another field where CARBOTRADE technologies are useful. They can be used in a number of applications, including the manufacture of containers, cables, plastic moulding and many more.

In every instance, the injection of high-purity, high-pressure nitrogen is central to the business, and process efficiency and quality are based on it.

Our solutions are suitable for all these applications. We listen to your needs, we design a customised solution and we support you in your gas management processes in the plastics industry.

We are also involved in the production processes in the perfume industry, especially for inerting perfumes.

Nitrogen is an inert gas. Thanks to this property, it does not alter the composition and properties of the components with which it comes into contact. This is called inerting.

In the perfume industry, inerting is essential to guaranteeing aroma quality. Our certified solutions guarantee that your efforts for excellence shall be preserved.

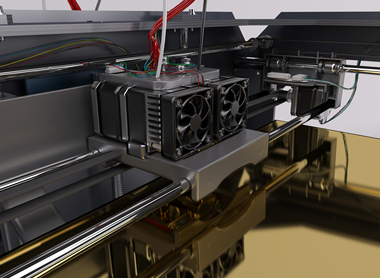

Prototyping machines can be found in a number of industrial sectors. They are an important equipment in the product design phase, and they require the supply and control of gases.

By managing pressure and purity, you can improve prototype quality, bringing a large number of benefits to your business. CARBOTRADE helps you design and improve your use of gases, combining our expertise with controlled production.

If you require on-site nitrogen production, CARBOTRADE can provide you with equipment and solutions for any industrial application.

There are many benefits in producing your own nitrogen:

These are all benefits of on-site nitrogen generation.

As specialists in nitrogen generation, we have a wide range of equipment to suit your needs, and we design customised solutions based on your project, in order for you to control your production process.

m3 of nitrogen produced per day

countries equipped worldwide

nitrogen generators manufactured