Custom-designed nitrogen generators

Nitrogen supply is a challenge for a number of industrial activities. With issues such as high costs and stock logistics constraints, there is a real interest in on-site nitrogen generation.

ABSOGER stands out as a major player in the field, with customised solutions adapted to your project, to help you fulfil your nitrogen needs and ensure economies of scale by cutting out the need for regular external supply.

Benefits

- Providing our clients with maximum flexibility in our products’ features.

- Manufacturing customised equipment (dimensions, international standards, etc.) in the best possible way to meet the most specific needs.

- Guaranteeing full control over the project, from conception, design to manufacture.

- On-site installation and training of your team members.

- Equipment maintenance and after-sales service.

All our equipment is designed and manufactured in our factory in the South West of France.

ABSOGER is a turnkey customised solution for nitrogen generation, a 100% Made in France solution.

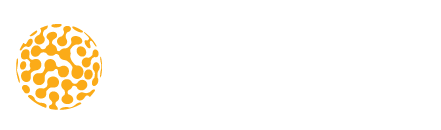

System components

ABSOGER has developed a high efficiency air pre-treatment system installed with PSA type nitrogen generators. Depending on the size of the nitrogen generator and the characteristics of the installation site, the machines can be assembled on one or more platforms (skid) or in a container, to facilitate transport and immediate adaptation to the production site.

The elements of the air supply chain are adapted to the characteristics of each generator and to the final application of the nitrogen.

The air is compressed by the compressor and then stored in a tank to provide the inlet pressure.

The air is treated by a refrigeration dryer to reduce the humidity of the air and then passed through particle filters to purify and de-oil it.

Finally, the purified air enters the generator to be treated by an activated carbon process that filters out the oxygen and keeps only the nitrogen.

ABSOGER also offers to equip your nitrogen generation system with an oxygen analyser and HMI display, so that you can analyse the oxygen at the nitrogen outlet and retrieve and record data on important parameters (flow rate, purity, etc.) for storage or study.

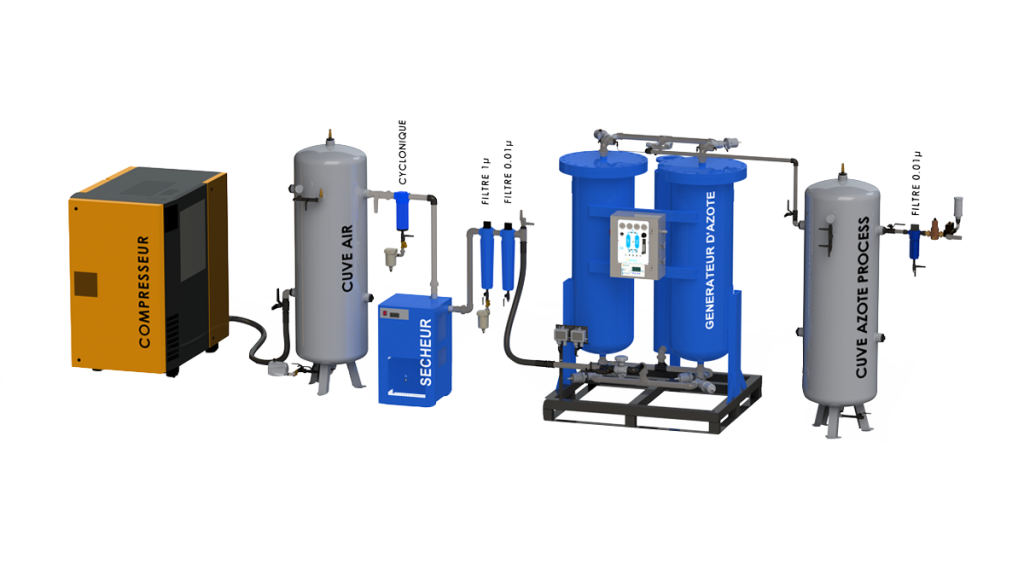

Containerised nitrogen generator

Elements of the air supply chain are adapted to each generator’s features and to the nitrogen’s final application.

The system includes the same components as a conventional PSA but is fully integrated into a container. This means it is easier to transport and can be immediately adapted to the production site.

Fields of application

Fruits & Vegetables

30 years of expertise ensure you can trust us with the preservation of your products.

Wine

We combine your expertise with our technology, so that your efforts in quality are rewarded.

Seeds

We provide the biggest seed companies with non-chemical processes in order to preserve life and product quality.

Cold room

We combine our expertise in insulation and sealing for ultimate atmosphere control.

Industry

Our solutions are used to upgrade the production processes of a large number of French manufacturers.

Oil & Gas

We protect the resources of the world's largest oil and gas producers.

Prévention incendie

For us, it is clear that prevention is the best protection.

Heritage

We preserve the Mona Lisa, we have the expertise to preserve the priceless.