A nitrogen generator is an industrial system used to separate nitrogen from other gases in the ambient air, using a compressed air inlet, providing a varying flow and purity depending on the various applications.

Today, PSA and membrane systems are an appealing supply mode for a wide range of volumes, purities and applications. The former are based on adsorption, while the latter are based on selective permeation.

ABSOGER produces two types of nitrogen-generating technologies, in order to fully accommodate the client’s needs: PSA (Pressure Swing Adsorption) technology and membranes.

PSA technology

The PSA technology consists of separating the oxygen from the nitrogen contained in the ambient air at low pressure using a molecular sieve of activated carbons.

- PSA technology (Pressure Swing Adsorption): Adsorption by pressure variation.

- Need compressed air drying and purification

- 2-column generators with CMS activated carbon

- Continuous generation of stable, high-purity nitrogen.

- High purity levels (>99.9%).

Gen2ius: Technical specifications

- Purity of the nitrogen produced: from 95% to 99,999%

- Nitrogen flow rate: 1 to 130 Nm3/h – higher flow rates available on request

- Nitrogen outlet pressure: 5 to 330 bar

- Number of columns can be increased

- Low energy consumption

- Long-lasting activated carbons

Gen2ius Range

GA: Technical specifications

- Purity of the nitrogen produced: from 95% to 99.9999%

- Nitrogen flow rate: 1 to 2000 Nm3/h – higher flow rates available on request

- Nitrogen outlet pressure: 5 to 330 bar

- Low energy consumption

- Long-lasting activated carbons

GA Range

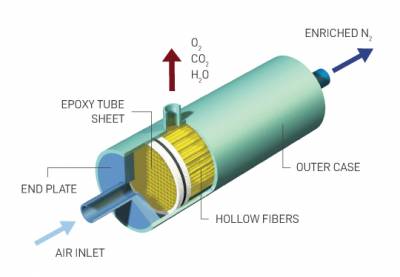

Membrane Technology

- Medium or low purity levels (<99.9%).

- Need a dry air supply

- Hollow fibre air filtration

- Selective material permeability

Technical specifications

- Purity of the nitrogen produced: from 95% to 99.5%

- Nitrogen flow rate: 1 to 2,000 Nm3/h – higher flow rates available on request

- Nitrogen outlet pressure: 5 to 330 bar

- Compact weight and size

- It is possible to change a membrane without stopping the generator