Controlled Atmosphere for R&D

CA preservation has proven to be beneficial for the storage of a number of fruits and vegetables, mostly produced in Europe. Therefore, for a number of other fruits and vegetables, expertise is still lacking.

In order to test how a new type of product responds to Controlled Atmosphere before investing in a full-scale installation, it is advisable to carry out preservation trials with an R&D type system.

ABSOGER has designed customised solutions to help you set up your research projects.

Benefits

ABSOGER’s Controlled Atmosphere system for R&D can be used by any entity (research centres, universities, R&D departments, agricultural laboratories) to carry out tests with different product varieties, under suitable storage conditions, in order to determine the appropriate gas levels for a specific product. This is to improve long-term preservation or preservation during transport.

The system does not require airtight chambers: storage in traditional cold rooms is sufficient.

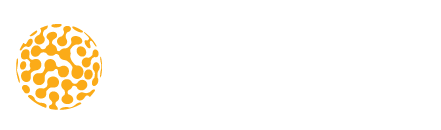

A ready-to-use post-harvest laboratory

With this solution, you can have your own laboratory within walking distance and within budget.

The entire atmosphere-controlled system is integrated into a container; from the machine room to the cold chamber and other additional equipment.

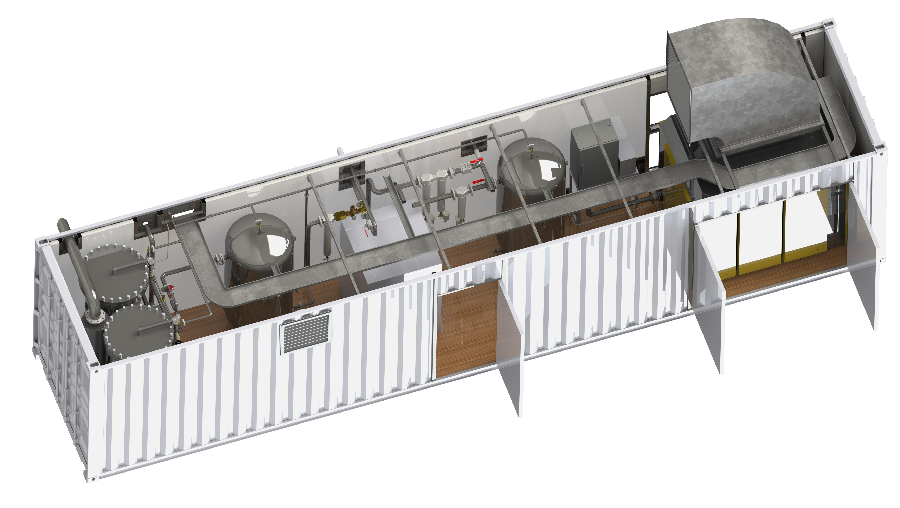

How it works

In order to carry out tests with small product quantities, preservation tests are carried out in a small-scale airtight chamber or inside airtight box pallets.

Tests can therefore be carried out under various storage conditions (1 tray = 1 CA storage method), in order to broaden research possibilities and save time.

The machines run until the set value is reached.

Innovation

Since its inception, ABSOGER has been working closely with the main agricultural research centres in France, in a continuous innovation process.

This collaboration has resulted in numerous public and private partnerships, and partnerships with institutions such as the CTIFL.

ABSOGER also has its own experimental chambers, where a large number of tests are carried out every season in order to remain at the cutting edge of technology and put innovation into action to provide solutions adapted to your needs.

Field of application

Fruits & Vegetables

30 years of expertise ensure you can trust us with the preservation of your products