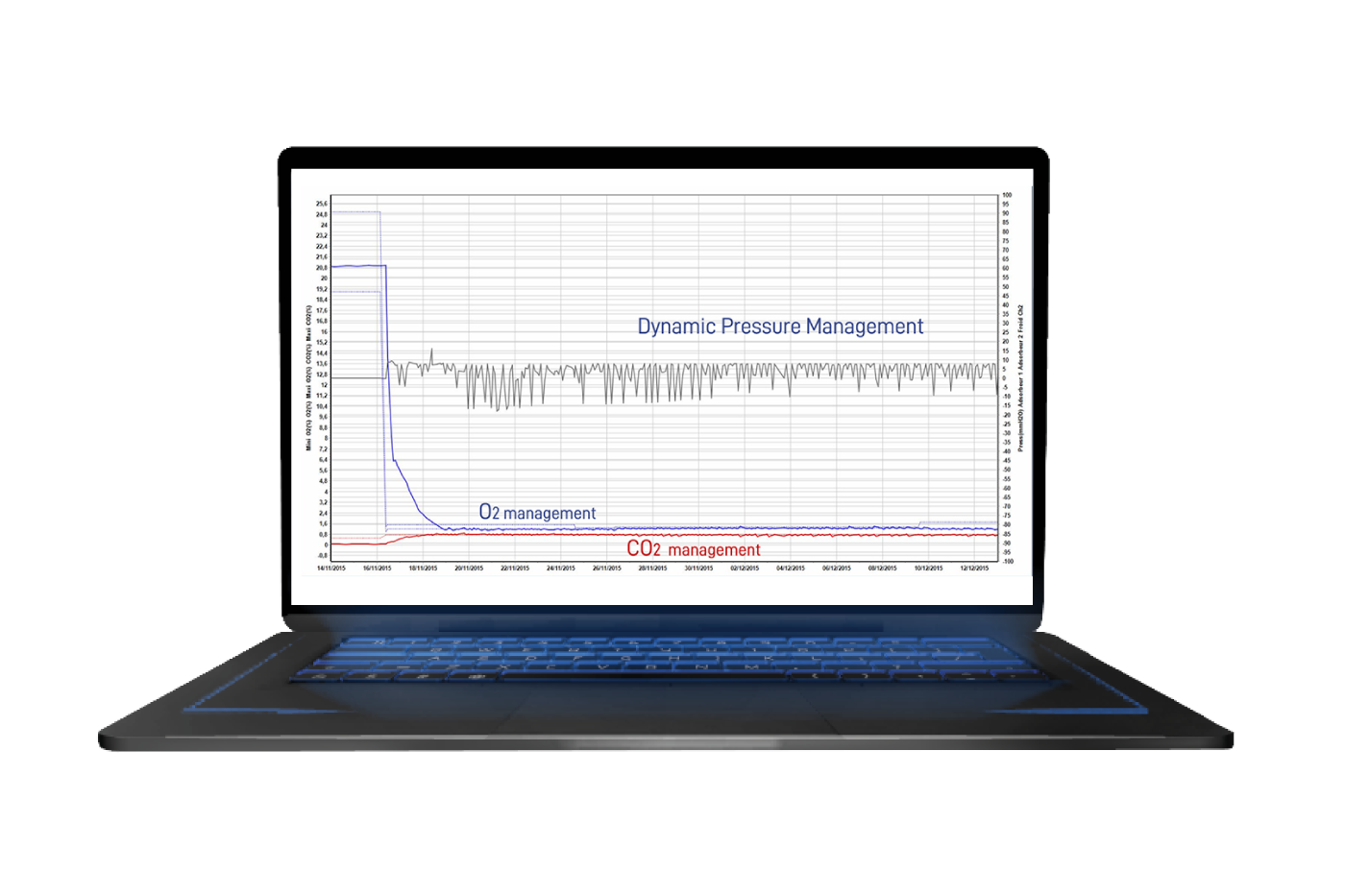

Pressure Management

Oxygen increases in Controlled Atmosphere (CA) chambers are mainly due to refrigeration systems starting, putting the chamber into a slight vacuum. The pressure drop causes oxygen to enter the chamber through the leaks.

Dynamic pressure management compensates for these oxygen inputs by maintaining a slight overpressure in the chamber.

Benefits

ABSOGER is there for you at each stage of the preservation process, helping you get off to a good start and adapt the use to your needs, with a number of benefits:

- XLO preservation possible in all types of chambers

- Lower nitrogen consumption

- Energy savings

- Preservation of the equipment’s activated carbon

- Better sealing: maintains ULO and XLO rates even in old, insufficiently sealed CA chambers.

- Option to carry out automatic airtightness tests controlled by the supervisor (with latest generation adsorbers)

- Higher storage quality

In addition, these solutions adapt to your equipment: for XLO as well as ULO or CA chambers, whether new or existing, pressure regulation also compensates for O2 ingress due to poor sealing.

Product presentation

Dynamic pressure management prevents oxygen ingress caused by several factors and poor sealing.

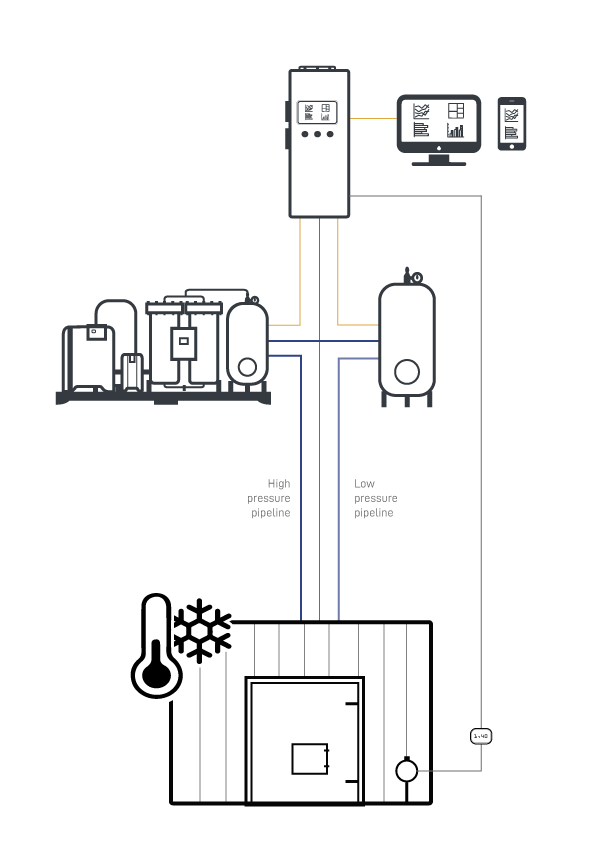

The system consists in constantly maintaining a very slight overpressure inside the CA chamber by injecting nitrogen micro-pulses only when necessary.

Real-time measurement of the pressure in the chamber: pressure sensor connected to the automatic management system.

- Electrovalve to regulate the pressure inside the chamber automatically.

- Pressure variations inside and outside the chamber are compensated for by micro-pulses of nitrogen and by air inlets.

- Customisable configuration for each operating mode (cooling, AC, long term storage, AC opening, personal safety)

- Integration in the different views of the Supervisor V7 software.

- A high quality pressure sensor with real time measurement and automatic self-calibration

- A fixed nitrogen generator (O2 purity about 1%)

- A nitrogen reserve (sized according to the volume of the chambers)

- An automatic low pressure injection network with controlled electrovalves

- A safety valve per chamber, automatically controlled

- A hydraulic guard with overpressure valve

- An automatic control software (Automatic Management Supervisor V7 ABSOGER)

Field of application

Fruits & Vegetables

30 years of expertise ensure you can trust us with the preservation of your products.