Treatment of seeds by anoxia

Seeds should be stored in certain conditions to maximise longevity while keeping storage costs reasonable. Several studies have shown the adverse effects of oxygen on seed shelf life (Groot et al., 2012). They are often stored in various types of containers with varying levels of oxygen permeability depending on the container, so O2 levels can be relatively high.

So it is a common practice in the food industry to package seeds (sunflower, pumpkin, nuts…) in oxygen-tight containers and under pressure, or in an anaerobic atmosphere to prevent them from becoming rancid due to lipid oxidation.

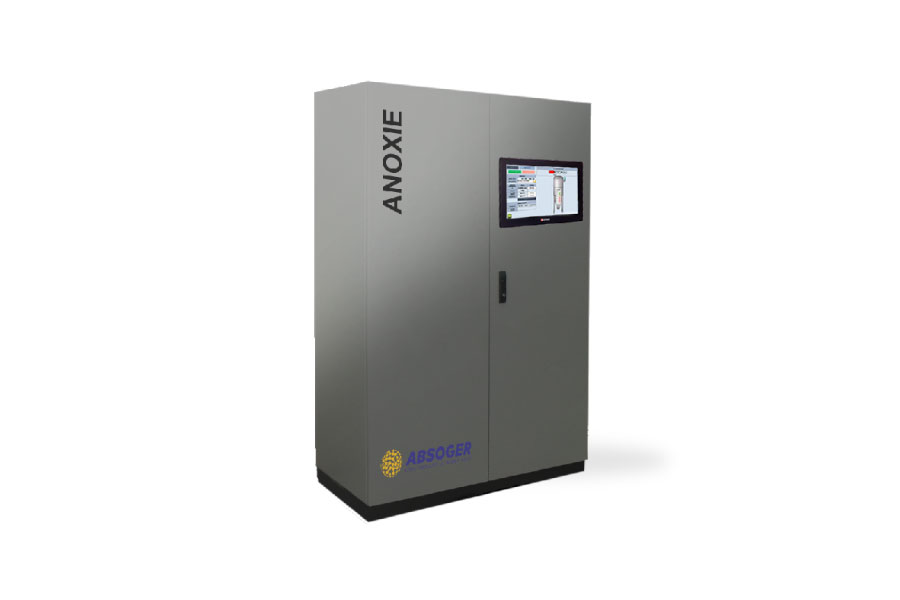

ABSOGER’s solution is used by seed companies and GeneBanks to take control at various stages of the transformation process and to prevent insects from appearing at every stage of development.

Benefits

ABSOGER offers a reliable alternative with the increasingly restrictive legislation and a solution for insect resistance to chemical processes, ensuring your batches can be properly sold.

Our solution is a guarantee against any possible degradation of the biological properties of the grain (nutrients and germination capacity), while enhancing the quality of the seed stored by eliminating 100% of the risk of insect development at all stages of the process.

In addition, by using a 100% natural solution, you’ll avoid the dangers of handling insecticides, as well as any risks of contamination from storage entities and the constraints of Maximum Residue Levels (MRL).

A solution which adapts to your needs, a customised implementation and personalised support are the key factors of your project’s success with ABSOGER.

How it works

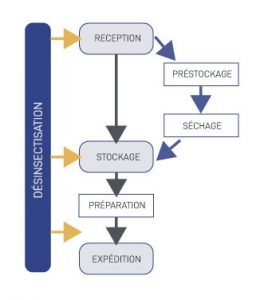

Treatment by anoxia is completely adapted to the seed management process. Treatment can be done in a sealed chamber, or directly on the storage silo.

A pneumatic system periodically takes samples of the air in the chamber. These samples are analysed in real time in the automatic management system.

Automatic management triggers the operation of the nitrogen generator. An algorithm allows the machines to run for the time necessary to reach the set rates.

The machines run continuously until a certain pressure is reached in the nitrogen storage tank.

This storage tank supplies nitrogen to the network according to the needs of the chamber or silo. Once the pressure is too low, the generator fills the tank again.

Field of application

Seeds

We provide the biggest seed companies with non-chemical processes in order to preserve life and product quality.