ULO / XLO Controlled Atmosphere

By storing in a controlled atmosphere, you can preserve some fruit and vegetables two to three times longer than in standard cold storage and keep products much fresher and firmer.

Always at the forefront of technology, ABSOGER has developed systems to preserve fruit in ULO (Ultra Low Oxygen) and XLO (Extreme Low Oxygen), combining O2 and CO2 conservation rates between 0.7 and 1%, ethylene control and dynamic pressure management in the chambers.

Benefits

- No stress for the fruit or the operator

- Excellent results in preventing SCALD in apples

- Fruit stays firm and retains its other qualities (juiciness, colour, etc.)

- Long shelf life

- 100% natural solution, no chemical treatment

- Customised equipment, regulation is proportional to your needs

- Energy and maintenance savings

- Comprehensive, fully automated system

Equipment

Nitrogen generation

Nitrogen generators for every industrial application.

CO2 adsorption

Adsorption adapted to volumes and storage methods.

Controlling ethylene

Analysing and removing ethylene makes it possible to control C2H4 levels in the CA chamber precisely, for effective preservation.

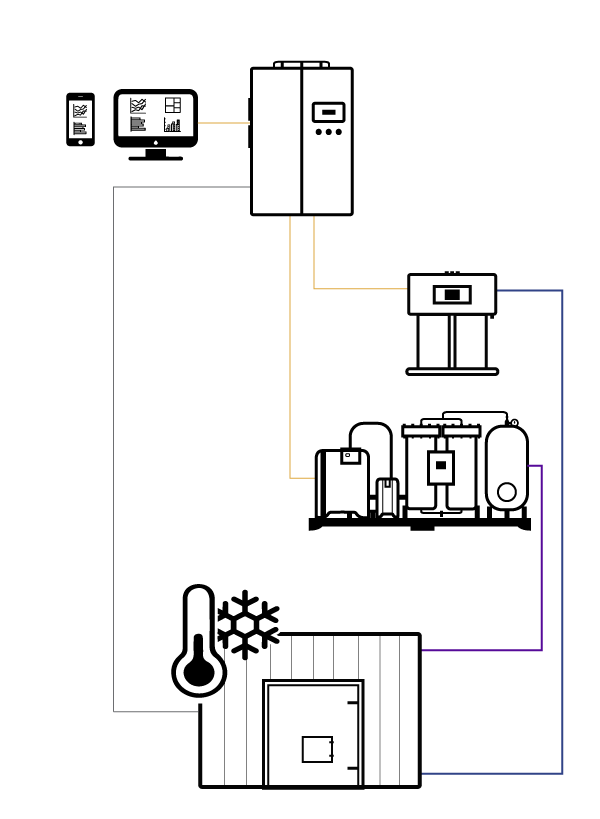

Control system

Automation of gas control equipment to ensure traceability, safety and user peace of mind.

How it works

Since fruit breathes differently from one variety to another, it is important to know the different varieties stored when sizing the CO2 adsorber and to take this information into account when choosing the right adsorber for your project.

A nitrogen generator will allow you to quickly lower the oxygen level after closing the chamber to stop the respiration of the stored fruit more quickly. It is recommended to lower the oxygen level in the chamber within 48 hours.

For the storage of kiwifruit and fruit with high ethylene sensitivity, it is imperative that Controlled Atmosphere chambers are equipped with ethylene catalysts to maintain a very low ethylene level in the chamber. An ethylene analyser monitors the level of ethylene in the chambers and allows preventive action if necessary.

A pneumatic system periodically takes air samples from the chamber. These samples are analysed in real time in the automatic management system or via an O2/CO2 analyser integrated into the adsorber, allowing daily monitoring of the oxygen and carbon dioxide levels in the chambers.

Our CO2 adsorbers can be operated in several chambers and controlled by an automatic management system. The management triggers the operation of each connected device. An algorithm allows the machines to run for exactly the time needed to reach the set rates.

The machines run until the set value is reached.

Field of application

Fruits & Vegetables

30 years of expertise ensure you can trust us with the preservation of your products.